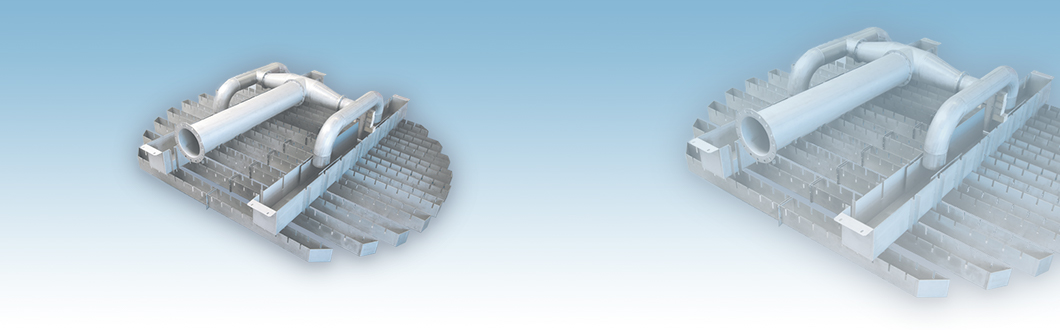

Liquid Distributor

Distribution of the liquid onto the packed bed or structured packing is provided by appropriate liquid distributors. It is important to distribute the liquid flow equally across the column area in order to secure an intensive mass transfer between the phases. An important design criteria is the number of drip points in relation to the column area (= irrigation density).

Liquid Distributor

| Types | Materials of construction | ||

|---|---|---|---|

| Metal | Plastic | Ceramic | |

| Pan-type distributor | M 150 T | P 150 T | K 150 T |

| Deck-type distributor | M 150 B | P 150 B | - |

| Ladder-type distributor | M 150 RR | P 150 RR | - |

| Spray nozzle-type distributor | M 150 SR | P 150 SR | K 150 SR |

| Trough-type distributor | M 150 KK | P 150 KK | K 150 KK |

| Trough-type distributor with integrated parting box | M 150 KQ | P 150 KQ | - |

Other types or special designs

on request.

In addition to the requirement for regular liquid distribution the internal has to meet following requirements:

- pressure drop in the gas phase should be low,

- part should be resistant against dirt or solids in the liquid,

- high turn down ratio,

- low entrainment of droplets,

- prevention of irregular gas distribution,

- prevention of wall effect on liquid flow.

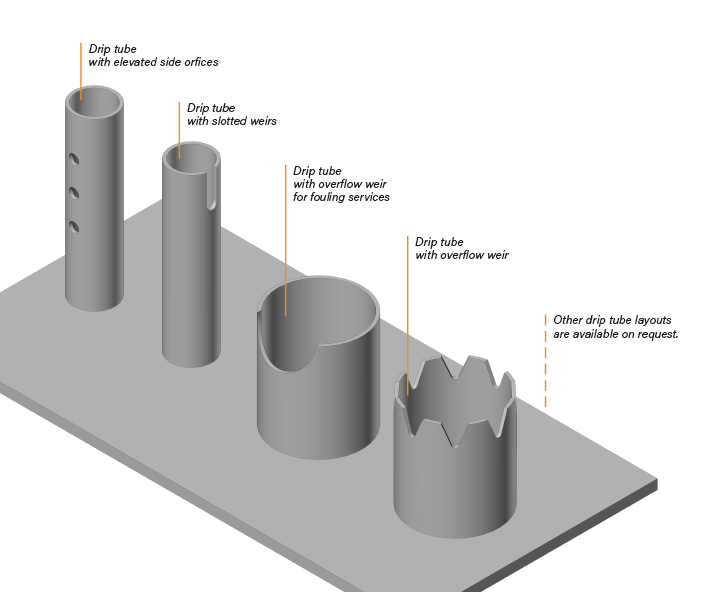

Following principles of liquid distribution are used:

- by orifices at the bottom of distribution troughs or by drip tubes with side perforations

- overflow distribution by slots at the side of the troughs or by overflow spouts

- nozzles.

Each of the mentioned design types of a distributor and the liquid distribution have their specific applications. We are happy to support you with our knowledge and experience in designing column internals with respect to your specific requirements (such as column diameter, flow rate and working range).