Ammonia Recovery

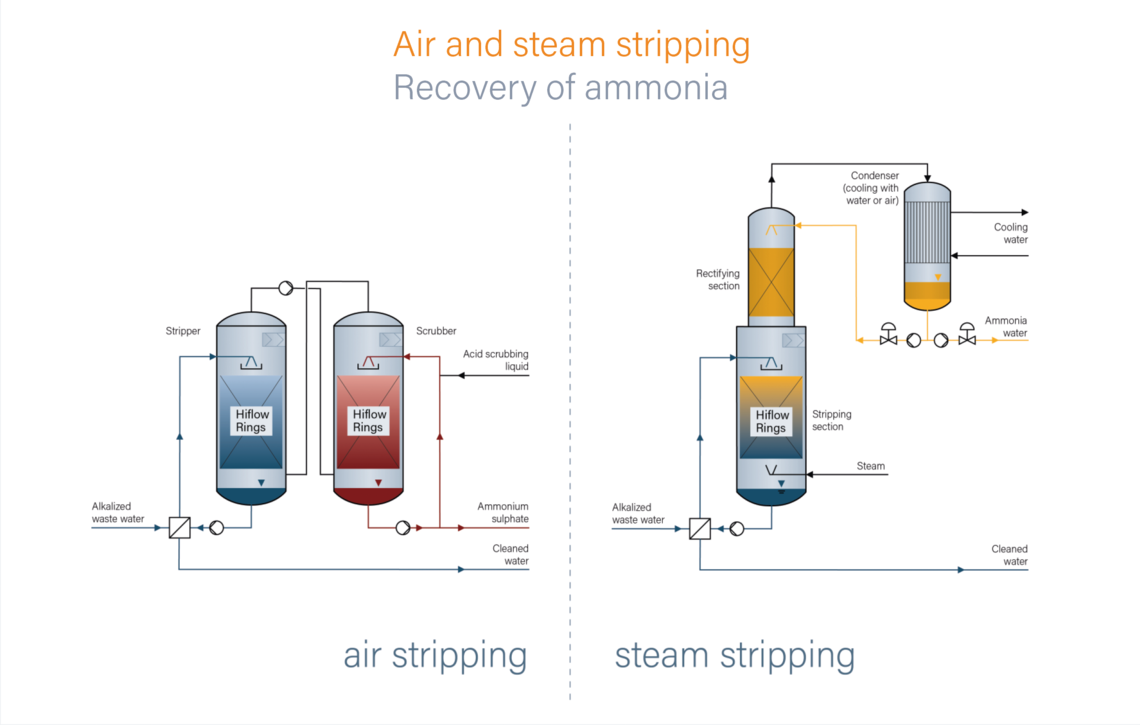

Industrial and municipal wastewater streams as well as effluents from biogas plants are sometimes heavily contaminated with ammonium nitrogen. Stripping with air or steam is one of the known and safe methods of processing ammonia-containing wastewater.

Our systems represent economical and well-engineered solutions. The scope of supply extends from the pre-treatment of the waste water through the actual ammonia stripping to the production of marketable products.

From project planning to commissioning, we offer everything from one source.

The process

Ammonia can only be stripped in an alkaline environment. By adding caustic soda or lime milk, therefore, the pH is raised and released the ammonia. In order to reduce the buffer effect of the waste water and thus the lye consumption, upstream measures for CO2 reduction can be installed.

After air stripping, the NH3-laden air can be thermally recycled or further treated in an acidic wash. The rule is the chemical washing of ammonia with dilute sulfuric acid. The air is driven in a closed circuit between desorption and absorption column. The resulting ammonia sulfate solution is concentrated and utilized mainly as a liquid fertilizer.

In order to optimally adapt the process to customer-specific requirements, several process alternatives are available, such as

- Stripping directly with live steam or by circulation evaporator

- Stripping column with stripping section and, if required, with rectification stage to remove the ammonia-containing vapors up to max. Concentrate about 20% NH4OH

- Operation under atmospheric conditions or under reduced pressure

- Vapor condensation with cooling water or by means of air cooler

As a product of value ammonia water is generated. The purity of the overhead condensate allows reuse z. B. in DeNOX plants.

Stripping with steam is characterized by high efficiencies. Air stripping is generally the cheaper method and especially useful when no in-house steam and cooling water network is available.