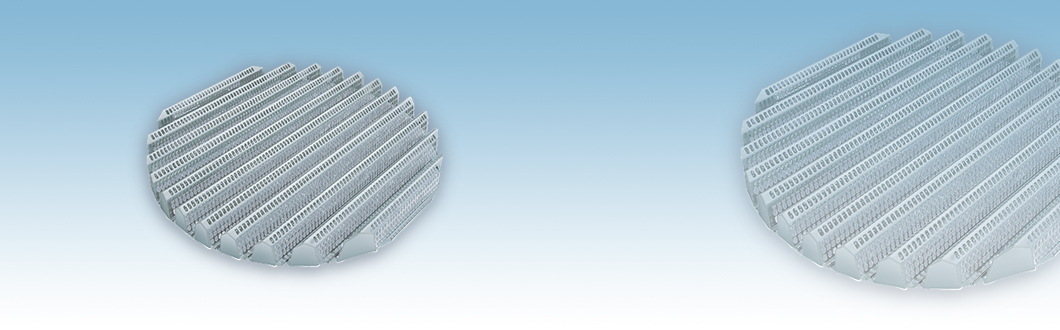

Support Grid

For supporting the packing in the column RVT Process Equipment manufactures a variety of support grids, specially designed for different applications and column diameters.

For the design of the specific grids, the following considerations are made with regard to the load of the grid:

- weight of packed bed

- liquid hold up during operation

- fouling

- pressure drop

- installation loads

The support grid must be constructed in a way that allows flow of gases and liquids in the column as unrestricted as possible. This is especially important in the area between support grid and packed bed.

Support Grid

| Types | Materials of construction | ||

|---|---|---|---|

| Metal | Plastic | Ceramic | |

| Flat support grid | M 65 | P 65 | K 65 |

| Profile support grid (low beam) | M 95 | P 95 | - |

| Profile support grid (medium beam) | M 165 | P 175 | K 180 |

| Profile support grid (high beam) | M 350 | P 250 | K 300 |

Other types or special designs

on request.

For the installation of a support grid, a support ring is needed, and sometimes intermediate support beams. The support grid may be fixed to the support ring with hardware or may rest flat on the ring, depending on operating conditions.